Caon Design Office introduces its concept aircraft seat, Modulo

Caon Design Office unveils its concept aircraft seat, Modulo, which employs 3D knitted Merino wool to create its semi-transparent skin and changeable covers. The office teams up with Woolmark for the Merino Wool, which is made of natural, renewable, and biodegradable fibers. While the aircraft seat design may hint at First Class cabins on airplanes, the material and technology used serve a general purpose and fit all kinds of arrangements, regardless of the seat class. As soon as the passengers sit down, they can feel the 3D-knitted wool blend membrane of Modulo, offering them a distinctive tactile feel even with its semi-transparent skin.

images courtesy of Caon Design Office

Woolmark teams up for modulo’s material

Caon Design Office and Woolmark concentrate on using a single material for their aircraft seat design, Modulo. Titanium, aluminum, and carbon fiber form Modulo’s structure and support its fabric membrane. These materials are used individually rather than blended to prop up the lightweight and robust framework of the aircraft seat. It’s already been established that the advanced 3D knitting techniques form the semi-transparent skin of the Merino wool membrane. But passengers may want to know that carbon and elastic polymers are integrated into the fabric to allow the seat to transition from an open space to a private enclosure, thus avoiding the use of traditional foam.

Caon Design Office teams up with Woolmark for the Merino wool of Modulo

A quick-release mechanism is in place for the aircraft seat design, Modulo. It allows for cover changing, and this feature is intended by Caon Design Office and Woolmark, who want to provide passengers with a new 3D-knitted Merino wool feel every other flight or season. The interchangeable cover also seals a guaranteed hygienic flight and less lengthy period for the airline staff to reconfigure or refit the aircraft seats. Caon Design Office keeps versatility in mind too, since the lightweight structure and modular nature of Modulo mean mass transport, hyperloops, autonomous vehicles, and electric aircraft can adopt the aircraft seat design and its 3D-knitted wool material.

as soon as the passengers sit down, they can feel the 3D-knitted wool blend membrane of Modulo

3D-knitted throughout the aircraft seat design

Another feature of the Modulo is the bench in front of the passenger, which doubles as storage. They lift up the lid, and the extra storage greets them. When not in use, the cushion on the surface is plush enough to hold their backs as they sit on it. On the side of the aircraft seat design, electronic devices can be stowed on the wooden shelf illuminated by ambient lighting, and remote workers can easily deploy and stow their movable table too.

titanium, aluminum, and carbon fiber form Modulo’s structure and support its fabric membrane

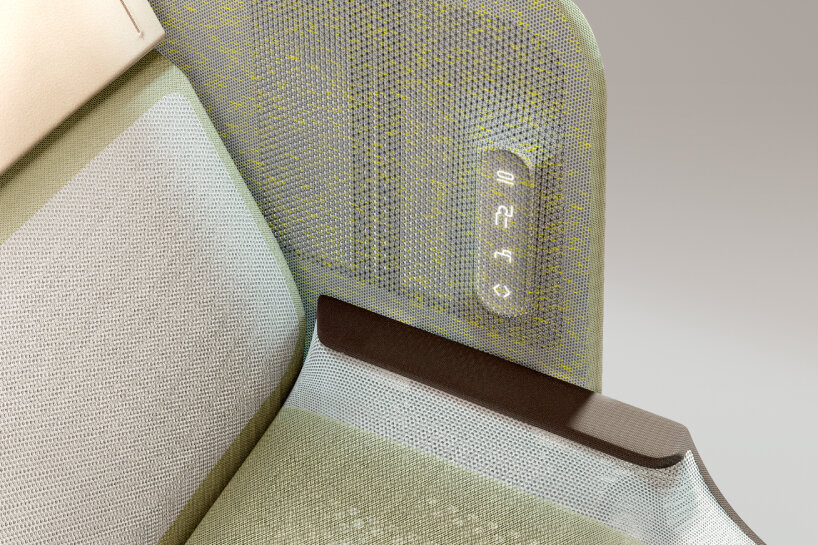

Embedded on the side of their seat, Caon Design Office adds the chair’s controls with temperature functionality, wrapped and injected into the 3D-knitted Merino wool of Woolmark. The combination of these features makes Modulo a platform of materials, shapes, and concepts rather than a specific configuration. It’s easy to see how Modulo plays with material properties and design outcomes, an approach reminiscent of Mario Bellini’s work with Olivetti. For Caon Design Office and Woolmark’s aircraft seat design, the texture of materials is underlined, along with experimenting with public privacy through the semi-transparent skin.

advanced 3D knitting techniques form the semi-transparent skin of the Merino wool membrane

Accommodating technology springs into the design too, since Modulo can be integrated with sensors that can actively monitor and regulate seat temperature. These sensors, hidden away by the thoroughly designed membrane of the aircraft seat, can prompt the passengers to move in their seats too and mitigate health risks associated with prolonged immobility, such as deep vein thrombosis (DVT). As of publishing the story, Modulo is a concept aircraft seat design, and Caon Design Office aims to materialize it for airlines in the future and after further research.

carbon and elastic polymers are integrated into the fabric to allow the seat to transition into a private enclosure